Factory Systems

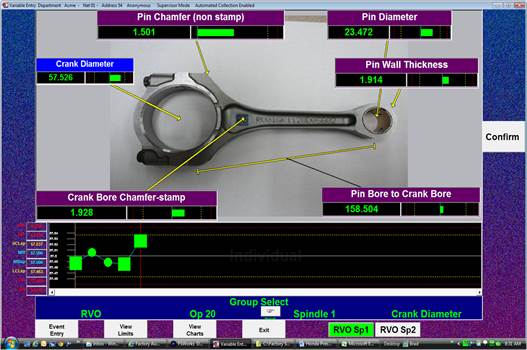

Factory Systems, LLC provides Statistical Process Control (SPC) in the form of data acquisition and analysis hardware, software and networked host systems. Formed in 1978 as Industrial Microsystems Inc. (IMI), engineers worked closely with a group of practicing process engineers to design rugged, extremely flexible industrial computers for data acquisition and SPC analysis including Six Sigma reporting. Gauge interfaces were added for Federal and Mitutoyo digital gauges, Heidenhain Glass Scale, LVDT, analog signals, and RS-232 data streams. The Host system software was created, providing networked administration and data management.

Factory Systems Products

Factory Systems Highlights

SPC and OEE Solutions

Factory Systems provides Statistical Process Control and Overall Equipment Effectiveness solutions to help you reduce costs. It is the most simple easy to learn, full spc system software, oee software, plant monitoring, and parts tracking software on the planet!

Optimized to Environment

FSWorksTM runs on a plant floor and provides for stand alone or network data collection. The application is optimized for a variety of manufacturing environments:

PC

NEMA 4X FS CimStatTM

Machine Tool

Fully Integrated

Lean Manufacturing

Our software has built in SPC data collection, machine efficiency (OEE), and parts tracking/tracing to meet your lean manufacturing needs

Parts Tracking

Customers are demanding that their suppliers provide them with information on every batch of parts. FACS can produce a quick report including SPC, OEE, and parts tracking/tracing information!

![]()